Proses Produksi Strip Galvanis

1. Pickling lan decontamination kabeh muter sakastrip steel kanggo entuk lumahing padhang lan resik.

2. Hot-dip galvanizing: Sawise pickling, wis di resiki ing tank saka amonium klorida utawa seng klorida solusi banyu utawa dicampur solusi banyu saka amonium klorida lan seng klorida, lan banjur dikirim menyang tungku annealing terus-terusan lan banjur menyang tank galvanizing kanggo galvanizing.

3. Strip galvanis lan dilebokake ing panyimpenan, lan lapisan galvanis bisa disesuaikan miturut kabutuhan pelanggan.

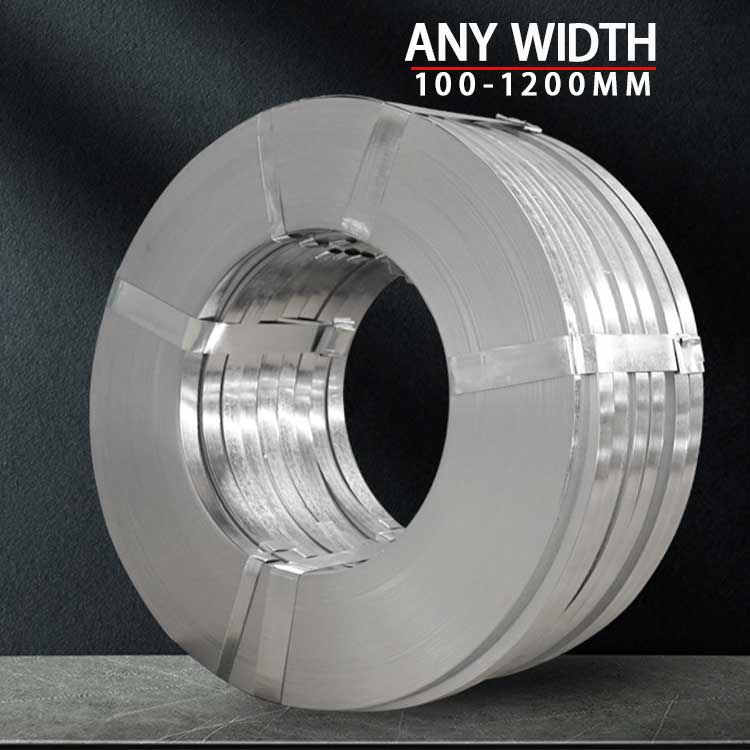

4. Yen ana syarat kanggo jembaré, ingkumparan baja galvanisbisa diolah dadi strip.Umume, kekandelan file keracunan yaiku 0.12-2mm.

Spesifikasi strip baja galvanis bisa disesuaikan miturut kebutuhan pelanggan.

| kekandelan | 0.12mm-3mm;11 gauge-36 gauge |

| Jembar | 50mm-500mm; |

| Standar | JIS G3302, EN10142, EN 10143, GB/T2618-1998, ASTM653, AS NZS 1397 |

| Kelas materi | SGCC, DX51D, G550, SPGC, lsp. |

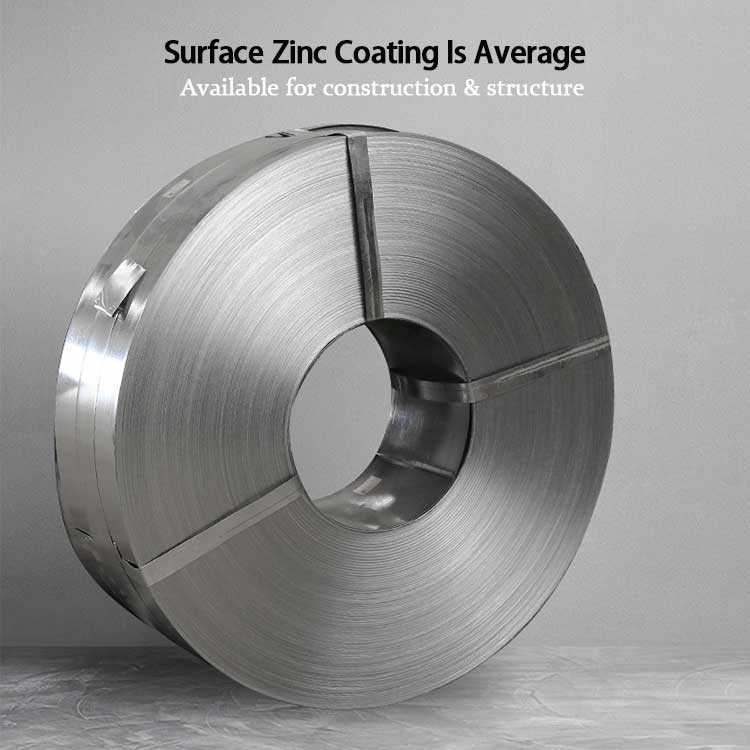

| Lapisan seng | Z30-Z275g/㎡ |

| Pangobatan lumahing | Passivation utawa Chromated, Skin Pass, Oil utawa Unoiled, utawa Antifinger print |

| Spangle | Cilik / Biasa / Gedhe / Non-Spangle |

| Bobot kumparan | 0.5-1 ton, siji paket biasane 3-5tons |

| Coil diameteripun njero | 508/610mm |

| Kekerasan | Soft hard (HRB60), medium hard (HRB60-85), full hard (HRB85-95) |

Koil / strip baja galvanis digunakake akeh kanggo konstruksi, bangunan, lembaran gendheng, mobil, tetanèn, peralatan omah, pipa Vanitation lan industri komersial.

Bahan dasar strip baja galvanis bisa dipérang dadi baja gulung kadhemen lan baja gulung panas.Ketebalan strip galvanis kanthi baja gulung kadhemen yaiku 0.12-2mm, dene ketebalan jalur galvanis kanthi bahan baja gulung panas yaiku 2-5mm.Kelas baja kanggo ngudani baja galvanis sing digulung adhem yaiku G550, DX51D + Z, S350, S550, Q195, Q235, SGCC.Strip iki umume irisan saka gulungan baja galvanis kang jembaré saka 600-1500mm, supaya sembarang jembaré Strip kasedhiya.